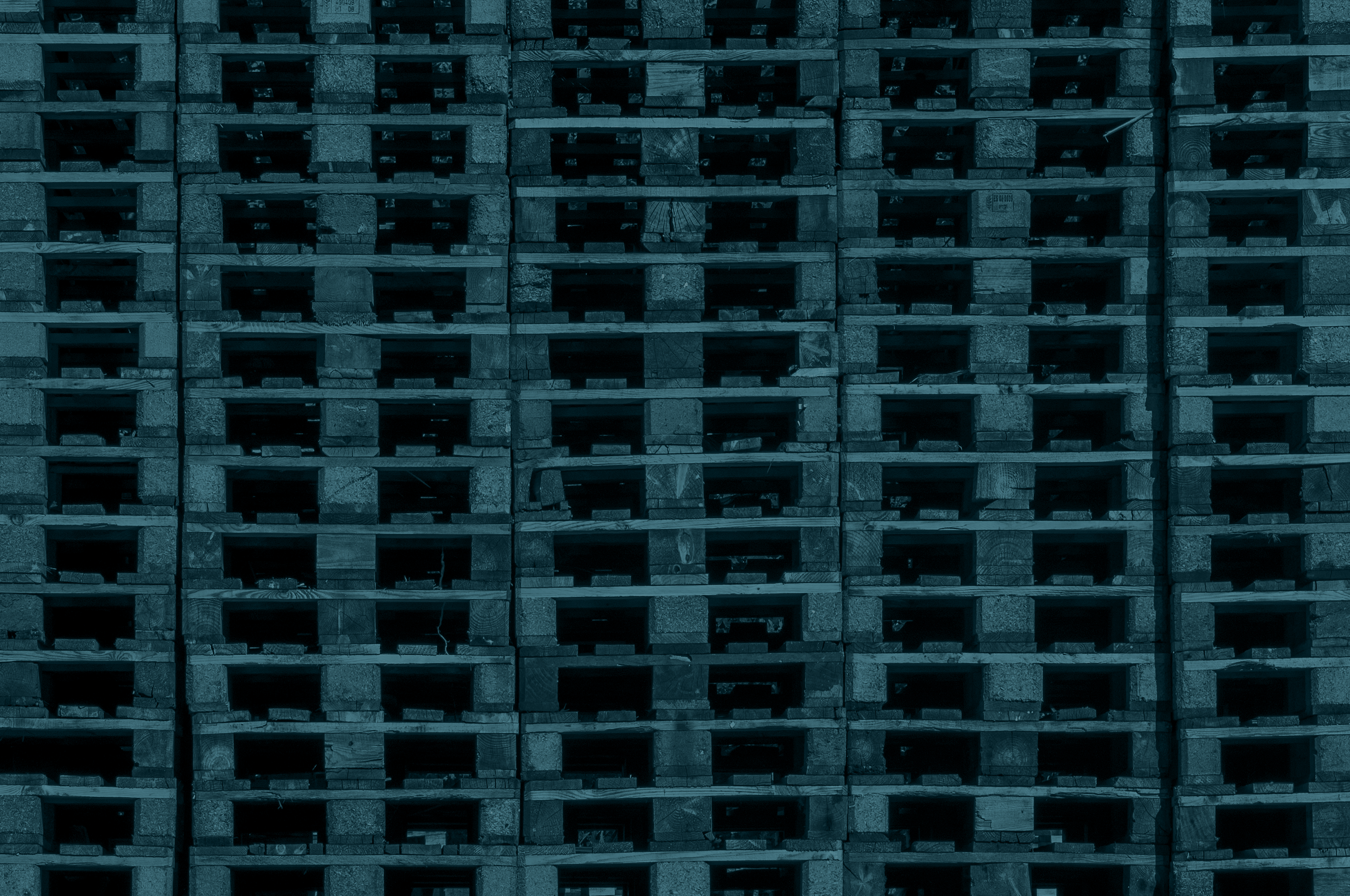

Do Your Palletizing Operations Stack Up? How to Choose the Right Automation Solution for Your Facility

Every business has its unique challenges. For those dealing with intricacies involved in palletizing operations, the choice of the right automation solution is crucial. Whether you’re an engineer seeking to reduce inefficiencies or a manager seeking to maximize uptime, Inspire Automation has you covered. In this blog post, we will guide you on how to choose an automation solution that best fits your operations and delivers cost-effective results.

Understanding The Need for Automation

In an increasingly competitive landscape where cost, speed to market, productivity, and communication are critical, businesses must invest in solutions designed to streamline their processes and make them more profitable. This is where Inspire Automation comes into play.

Inspire Automation, the merger product of two industry leaders, Automatan and Systec, has a complete catalog of innovative automation solutions created with your business needs in mind. We offer top-notch solutions in three main categories: material handling automation, robotic automation, and labelers and load turners.

During difficult economic times, the thought of investing in automation could be daunting. But consider this insight from Boston Consulting Group: companies that invested in operational efficiency during the 2001 recession reduced costs by an average of 10% and emerged stronger than before the recession. This highlights the importance of investing in the right areas, even during challenging times.

Common Inefficiencies in Palletizing Operations

Despite its importance, palletizing is often a bottleneck in the wharehousing process, with common inefficiencies hindering productivity. Before exploring potential automation solutions, it is essential to understand the problems that often plague typical palletizing processes.

- Manual labor dependency: The traditional palletizing process often requires substantial manual labor. This reliance results in increased labor costs, inconsistent pallet loads, and potential safety risks related to heavy lifting and repetitive motions.

- Time consumption: Manual palletizing is time-consuming, with employees often needing to manually sort, organize, and stack products. It can slow down the entire production line, and any delays in the palletizing process can cause further hold-ups downstream.

- Injuries and health risks: Manual palletizing often involves heavy lifting, which can lead to workplace injuries. Furthermore, repetitive movement over extended periods may give rise to musculoskeletal disorders amongst your workforce.

- Error-prone: Manual processes are subject to human error, leading to poor quality control and inconsistency in stack loads.

- Low scalability: Manual palletizing has a limited capacity and will struggle to keep up as your business grows and production scales up.

Benefits of Automation

Investing in automation solutions offers multiple long-term advantages that translate to better operational performance and profitability:

- Increased productivity: Integrating automated systems into your operations can significantly boost productivity. Automation systems can run uninterrupted, allowing your facility to operate 24/7 without a dip in performance. As a result, you will meet increased production demands with ease and potentially expand your target market.

- Enhanced accuracy: Machines can execute tasks with a high degree of consistency and precision. This ensures that mistakes attributed to human error are minimized, leading to better product quality and a more efficient operation.

- Worker safety: By implementing automation solutions, you can minimize the risks associated with manual labor activities. Automated systems carry out dangerous tasks, allowing your employees to focus on safer responsibilities.

- Lower labor costs: Automation can significantly reduce labor costs by streamlining processes and increasing efficiency. This enables facilities to handle larger workloads while maintaining lower staffing levels.

Inspire Automation Palletizing Solutions

Several solutions out there can revolutionize the palletizing process. Here is a quick look at some of them:

- Fully automated Gantry / Robotic Palletizing: Robotic palletizers use robotic arms to place the stack of corrugated product onto pallets. They are versatile, capable of handling different types of products with ease, and offer the highest volume and efficiency solution to warehouse palletizing needs.

- Pallet Handlers: For smaller space constraints, Inspire Automation also offer single pallet handler solutions that can palletize single pallet loads in a semi-automatic and/or automatic method.

- Mixed Case Palletizing: Mixed case palletizing is a sophisticated method of stacking different sizes and types of cases onto one pallet, creating a stable unit load. The AutoStak is an example of this form of robotic palletizing automation solution.

Choosing The Right Automation Solution

When seeking an ideal automation solution, it’s important to consider certain key factors.

- Efficiency: The right automation system should solve existing operational challenges and increase overall process proficiency. It should also have a swift execution time without compromising on quality, thus leading to increased productivity.

- Cost-Effective: A good automation solution should provide a good return on investment with cost-saving mechanisms.

- Robust Supplier Support: Choosing a provider with consistent, proactive communication and support ensures that your automation solution remains up-to-date and functional.

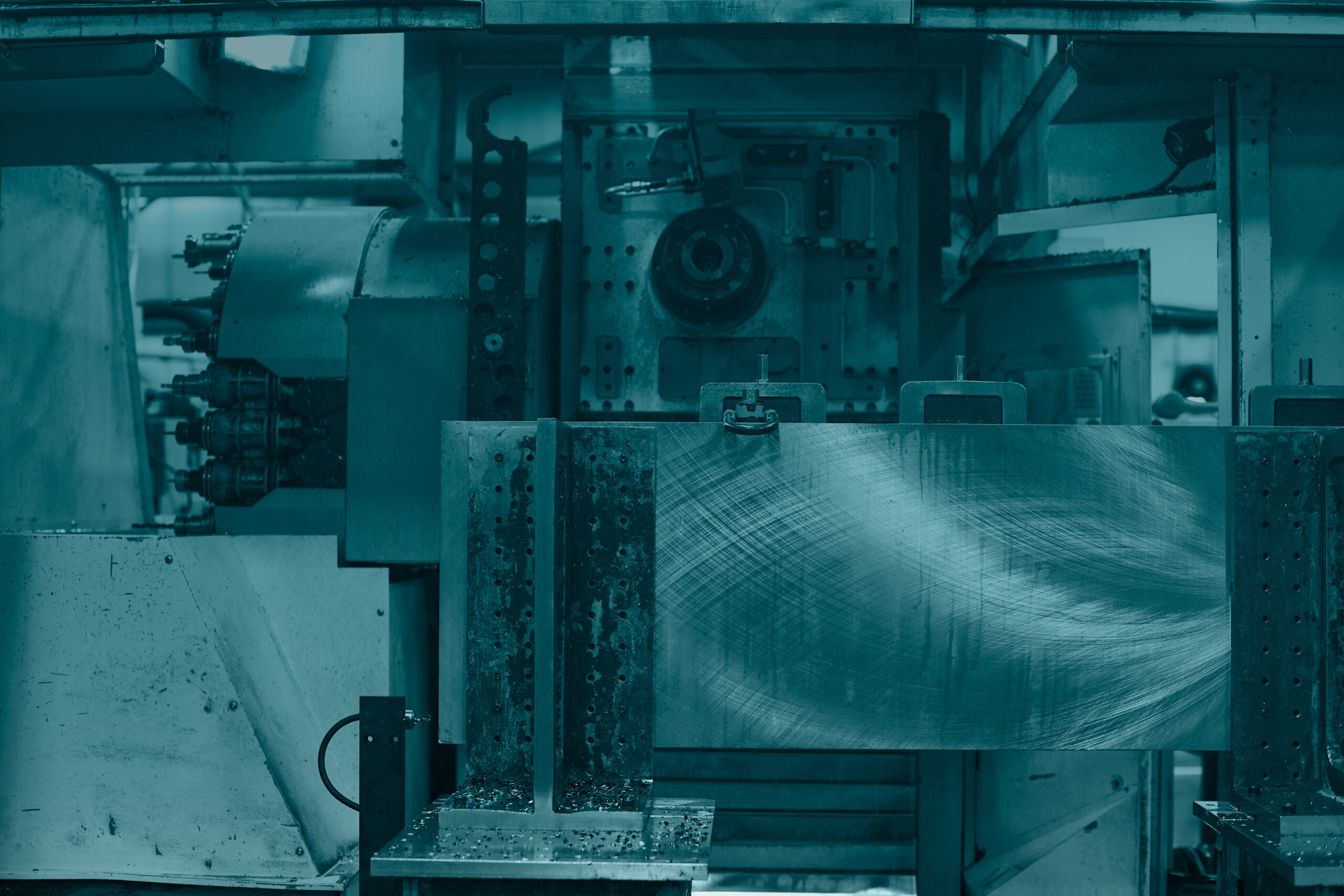

Unleashing the Power of Robotic Automation: AutoStak

Among our robust and diverse automation solutions array, one standout product is AutoStak, a revolutionary robotic palletizing system created with industry-specific needs in mind.

AutoStak leverages robotic automation, base-and-lid production, and advanced order change features to increase productivity, reduce waste, enhance safety, and ensure seamless operations.

Key Features of AutoStak

- Increased Efficiency: AutoStak palletizes boxes at a high speed, ensuring your operations are smooth, efficient, and productive.

- Safety: With an automatic system, the risk of human errors and injuries are considerably reduced.

- Robust Design: Its design integrates well with other systems, making it an ideal automation technology addition to your facility’s existing setup.

- Cost savings: AutoStak can lower labor costs significantly and reduce the need for costly machine downtime.

Is AutoStak Right for You?

Regardless of your industry, if you’re looking to optimize efficiency, reduce costs, and elevate productivity of your material handling processes, then AutoStak may be the perfect solution for your facility.

Throughout the chosen automation solution journey, Inspire Automation remains your steadfast partner, offering consistent communication, technical guidance, and proactive support. Our goal is to ensure that every investment you make in our automation technology brings value, efficiency, and an improved bottom-line. In a world of increasing complexity, Inspire Automation serves as your one-stop solution for all things automated.

Ready to elevate your palletizing operations? Reach out to Inspire Automation for a consultation—Send a Request today.

If you’re ready to implement high-quality automation solutions at your facility, we here at Inspire Automation are excited to work with you. Reach out today to learn about our high-quality hardware and support solutions. The world of manufacturing is changing, so let us be your partner for this exciting journey.

More from the Blog

Importance of Having Robust Software in the Automation Industry

Discover how robust software solutions like PLCs, HMI, DCS, and SCADA can enhance efficiency and productivity in industrial automation.

Read Full Article

Streamlining Material Handling in Non-Corrugated Facilities: Inspire Automation’s Tailored Solutions

Discover Inspire Automation's customized material handling solutions for non-corrugated industries. Improve efficiency and save costs with robotic and automation technologies.

Read Full Article