Efficiency and Precision: The High-Speed Capabilities of the Model 3710 STS Laminator

The Precise Laminating Needs of Specialized Markets

The burgeoning sectors of game cards, specialty advertising material, and custom mounting projects have unique requirements that standard manufacturing solutions can’t always meet. These products often require intricate designs, precise cutting, and flawless lamination – all while maintaining the essence of what makes them special. Companies operating in these markets face the challenge of producing high volumes of products without compromising on quality or uniqueness.

Inspire Automation leads the wave of advanced manufacturing solutions that optimize operations, bolster productivity, and drastically reduce downtime. In today’s challenging economic milieu, don’t think of automation as merely a way to cut costs—it’s a strategic investment for securing a bright, prosperous future for businesses. The Model 3710 STS Laminator, specialty laminator in Inspire Automation’s lineup, epitomizes precise, optimized material handling innovation.

Introducing the Model 3710 STS Laminator

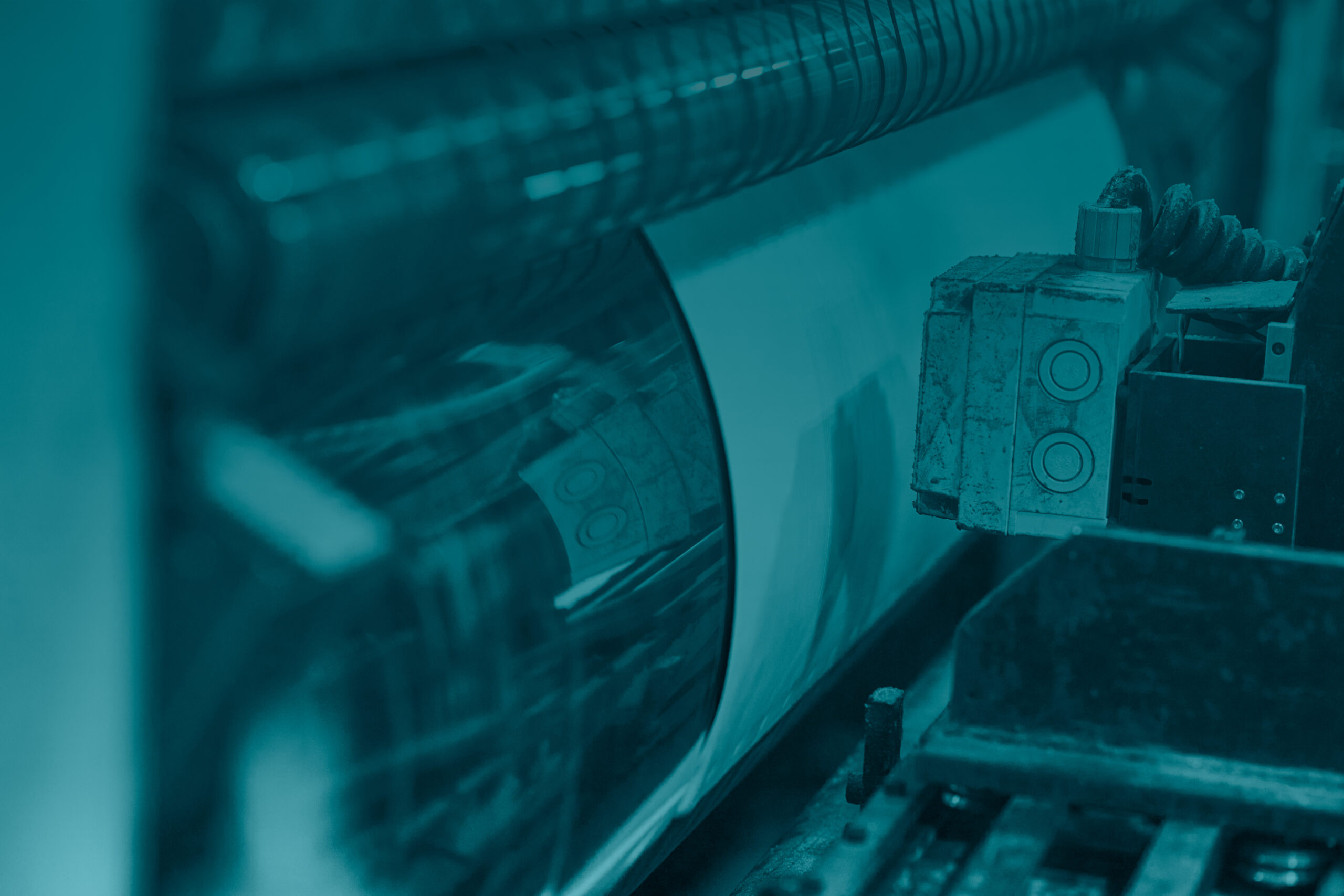

With the emphasis on precision, the Model 3710 STS Sheet-to-Sheet Laminator is engineered to meet the exacting needs of businesses demanding precise sheet edge to sheet edge registration. Distinguished by its rapid operation—capable of processing up to 6000 sheets per hour—and remarkable accuracy within a +/- 0.4mm tolerance, this laminator sets a new standard for performance excellence.

Key Features and Benefits

- Precision Registration: The Model 3710’s design achieves an exceptionally accurate sheet edge to edge registration, maintaining a consistent tolerance of +/- 0.4mm. This capability is invaluable for high-precision applications, ensuring flawless alignment and significantly enhancing product quality.

- Advanced Glue Application: Utilizing cold set and dextrin resins, it introduces a cutting-edge adhesive system that applies glue in specific patterns tailored to each product. This initiative results in precise control over film thickness and adhesive application, delivering unwavering quality.

- Streamlined Operation: Its capability to manage high speeds and the inclusion of an innovative down stacker design enable uninterrupted manufacturing processes, shortening production times and reducing idle periods, which in turn elevates productivity and profitability.

Addressing Precision Lamination Challenges

The journey towards perfect lamination is fraught with obstacles—misalignment issues, inconsistent adhesive application, and downtime due to inefficient processes pose significant challenges. The Model 3710 tackles these problems head-on with its precision registration and advanced glue application technologies, ensuring that finished products meet stringent quality standards. This drastically minimizes waste and rework, addressing two of the most significant pain points in the lamination industry.

Operational Overview: Elevating Manufacturing Potential

The Model 3710 shines in its operational design, from its dual-cylinder laminating section to the precision glue application system and efficient down stacker component. Every aspect is designed with meticulous attention to detail, powered by state-of-the-art technology to ensure unsurpassed outcomes.

In industries where efficiency, reliability, and precision are non-negotiable, the Model 3710 STS Laminator is a game-changer. Particularly for businesses in rapidly expanding sectors like specialty advertising, game cards, and customized laminating processes, this equipment is not just an asset but a foundation for growth and market expansion.

Comprehensive Automation Solutions by Inspire Automation

In the arena of modern manufacturing, where the demands for efficiency, precision, and reliability continue to scale new heights, Inspire Automation stands as a beacon of innovation and excellence. With a rich legacy that seamlessly blends the expertise of Automatan and Systec, Inspire Automation has positioned itself as a pivotal player in revolutionizing manufacturing processes across various industries, including corrugated material, folding carton, and litho printing sectors.

Custom Tailored Automation Solutions

Understanding the unique challenges and requirements of each manufacturing operation, Inspire Automation prides itself on delivering tailor-made solutions that streamline processes, enhance productivity, and minimize downtime. Their competence spans across several domains of automation, including Material Handling Automation, Robotic Automation, and specialized equipment like Labelers and Load Turners.

Material Handling Automation

With an emphasis on simplifying complex processes, Inspire Automation crafts intricate material handling solutions that align perfectly with specific applications. Their engineered systems ensure operations can be conducted safely, accurately, and to their fullest potential.

Robotic Automation

In the corrugated industry and beyond, Inspire Automation’s robotic solutions stand out for their ability to optimize operations, leading to better overall efficiency and safety. Their offerings address the critical need for downtime reduction, showcasing their commitment to advancing operational capabilities.

Labelers & Load Turners

The specialty needs of operations that require litho-labeling, laminating, and load-conditioning are adeptly met with the industry-leading catalog of Automatan and Systec solutions within Inspire Automation’s portfolio. This ensures that every operational requirement, no matter how niche, is catered to with expert precision and efficiency.

Unwavering Support and Service

Beyond just equipment and technological solutions, Inspire Automation is dedicated to ensuring clients have the confidence and support necessary to succeed. They provide a wide range of support services, including technical support for upgrading and improving equipment, remote monitoring systems, and a comprehensive service program that ensures long-term operational efficiency.

A Partner for Progress

As businesses face the challenges of a rapidly changing economic landscape, the need for reliable, efficient, and precision-oriented manufacturing solutions becomes ever more critical. Inspire Automation, through its focused solutions and unwavering commitment to innovation and customer support, emerges not just as a provider of automation technology but as a true partner for progress. Their comprehensive automation solutions, exemplified by groundbreaking equipment like the Model 3710 STS Laminator, pave the way for manufacturing entities to not just navigate but thrive in the evolving industrial ecosystem.

For industries poised to leverage the full potential of automation, Inspire Automation offers more than just technology; they provide a foundation upon which businesses can build a future of success, efficiency, and innovation. Explore the breadth of possibilities with Inspire Automation and set your operations on the path to unparalleled excellence.

Inspire Automation: A Legacy of Innovation

Inspire Automation’s relentless pursuit of innovation, illustrated by the Model 3710’s success story, solidifies its reputation as a pioneer. Merging the rich histories of Automatan and Systec into a dynamic future, Inspire Automation remains dedicated to exceeding the evolving requirements of the industry.

Conclusion

Considering the push towards operational efficiency enhancement, the Model 3710 STS Laminator by Inspire Automation is a beacon of innovation and strategic foresight. For businesses eager to leverage automation for maximizing uptime and enhancing productivity, Inspire Automation emerges not just as a solution provider but as a partner in pursuing excellence. In the shifting economic landscape, judicious investments in technology such as the Model 3710 are crucial steppingstones to post-recession success.

At Inspire Automation, we pride ourselves not only on the innovative solutions we offer but also on the extensive support and service we provide to each of our clients. Don’t let the opportunity to enhance your manufacturing efficiency and product quality with the Model 3710 STS Laminator pass you by. Contact Inspire Automation today and take the first step towards a future where your operations are defined by precision, efficiency, and unwavering support.

More from the Blog

Streamlining Material Handling in Non-Corrugated Facilities: Inspire Automation’s Tailored Solutions

Discover Inspire Automation's customized material handling solutions for non-corrugated industries. Improve efficiency and save costs with robotic and automation technologies.

Read Full Article

Extended Service Agreements: Your Safety Net for Uninterrupted Performance

Long-term service and support agreements can be the guardrails for success in your industry. With Inspire Automation, these agreements are part of a commitment to our clients—a pledge to deliver uninterrupted service and steadfast support.

Read Full Article