Labelers + Load Turners

Our solutions use the latest technology to increase profitability and uptime.

Load Conditioning Equipment

Consistency and quality are factors that can make or break your business. Our load conditioning equipment—including labelers and litho-laminators, load-turners, and joggers/aerators—can dramatically reduce labor costs and increase overall uptime.

Legacy Equipment

NewPaks

The Automatan NewPaks sheet-to-sheet single-face laminator is a legacy device no longer in production. The SF65 is designed in the same configuration and has the same precise registration as the other Automatan labelers in production. Automatan’s single-face laminators, at speeds to 10,000 sheets per hour, competed very favorably with inline single-face laminating systems productivity, yet offered the flexibility and low waste of sheet-to-sheet for today’s varied jobs and run lengths. Simplicity, accessibility, small crew requirement, low adhesive consumption, negligible setup times, and low capital investment are all benefits with Automatan single-face laminators.

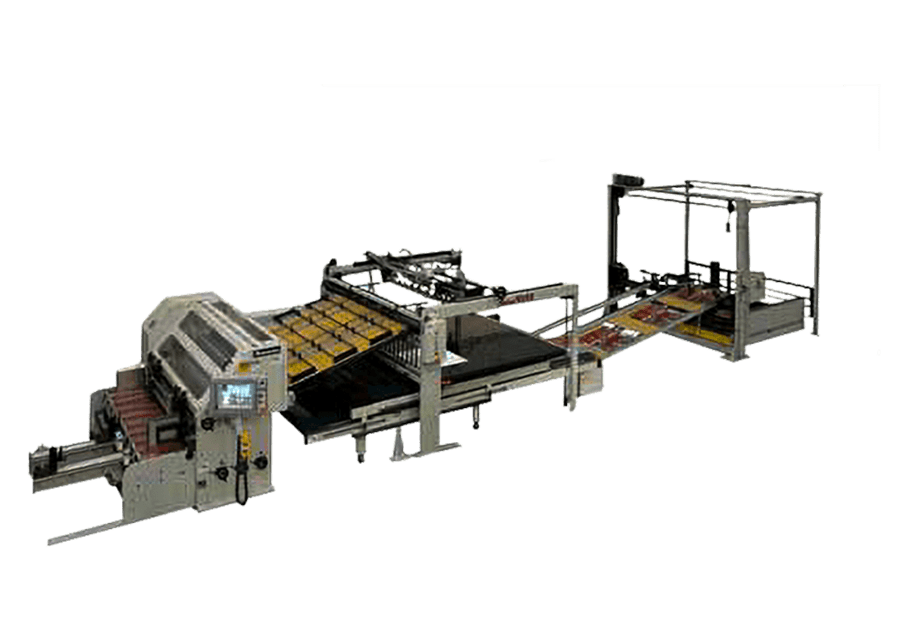

Model SF65

The Automatan SF65 sheet-to-sheet single-face laminator is a legacy device no longer in production. The SF65 is designed in the same configuration and has the same precise registration as the other Automatan labelers in production. Automatan’s single-face laminators, at speeds to 10,000 sheets per hour, competed very favorably with inline single-face laminating systems productivity, yet offered the flexibility and low waste of sheet-to-sheet for today’s varied jobs and run lengths. Simplicity, accessibility, small crew requirement, low adhesive consumption, negligible setup times, and low capital investment are all benefits with Automatan single-face laminators.

Model 4260

The Automatan 4000 Series Label laminators are legacy devices no longer in production. The 4000 Series labeler was considered one of the most versatile laminators in the world, include Automatan’s leading Model 4260, which is well known for its quick setups, cleanups, and precise registration over a broad range of substrates and labels at speeds over 5,000 sheets per hour.

Auto Max

The AutoMAX Labeling/Laminating System is a legacy device no longer in production. It had the ability to single-face laminate, spot and full mount litho sheets to corrugated sheets, knocked-down boxes, and diecut sheets.

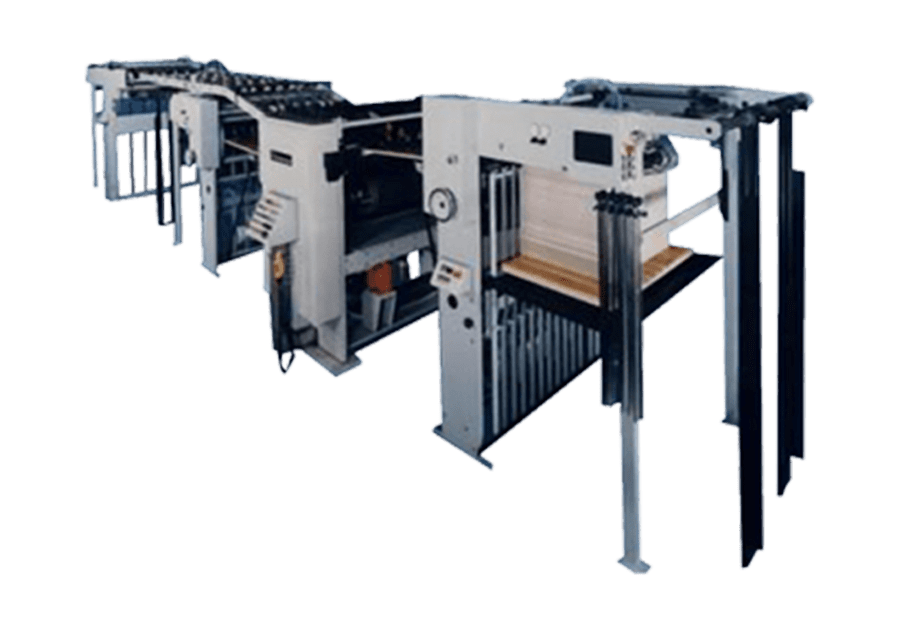

Model 7780

The Automatan 7000 Series labeler is a legacy device no longer in production. It delivers performance over a wide range of sizes. Its fast, easy setup makes it ideal for short runs as well as high-speed production. The Model 7780 laminator has been developed for large-format labeling and can spot, full, panel, and strip mount litho sheets to corrugated sheets, knocked-down boxes, and diecut sheets.

Labelers

Model 3710

Specialty laminating offers exciting opportunities for the fast-growing game card, mounting, and specialty advertising markets. Any printer with an eye on a profitable future in these markets will recognize the value of having the highest quality, fully automatic laminating equipment. Automatan specialty laminators are designed to laminate many products including pull-tab and bingo game cards, point-of-purchase display easels, duplex papers, re-moist glue patterns, children’s puzzles and game boards, and many other applications. Precise registration, consistent adhesive application, and high production speeds make Automatan pattern laminators the choice for specialty laminating.

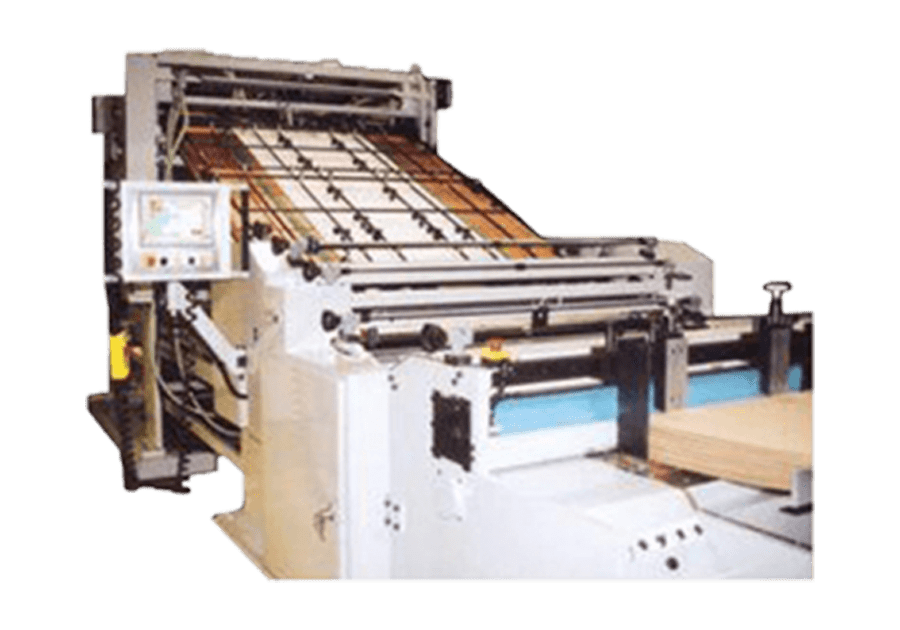

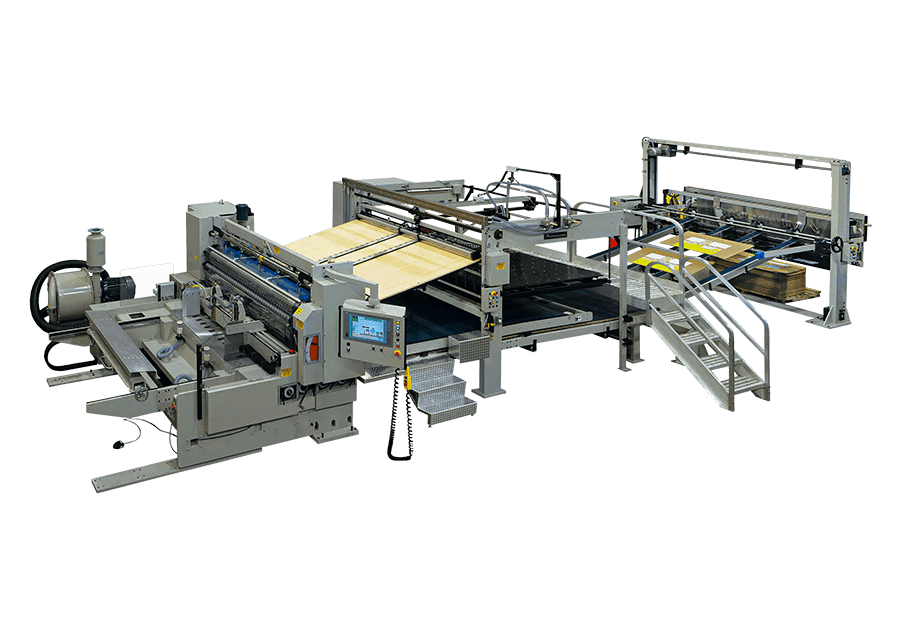

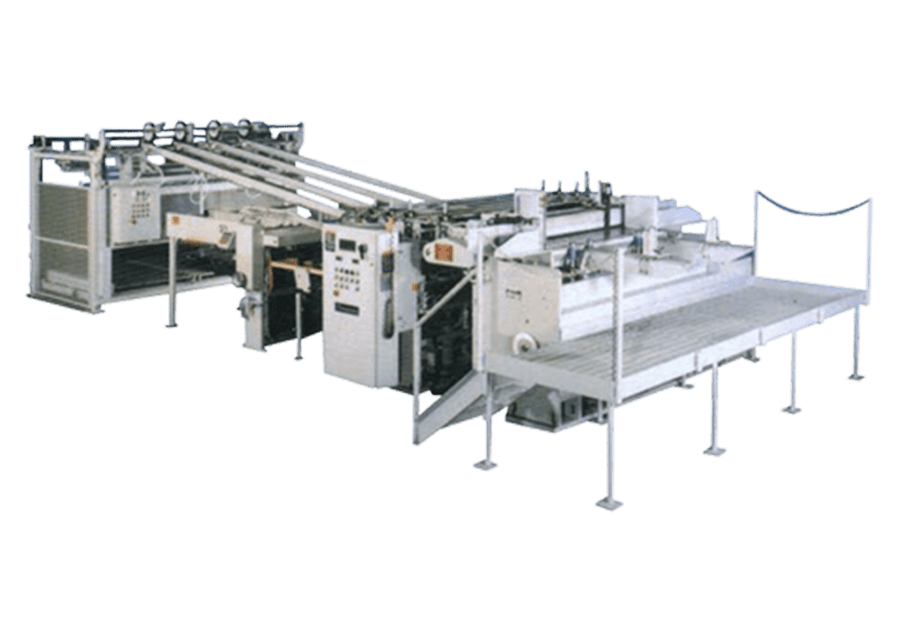

Model 8166 Litho-Label Laminator

The Automatan Model 8166 Litho-Label Laminator is shown with board feeder, laminating unit, label feeder and straight-through discharge to optional upstacker. This model full mounts or spot mounts litho-labels to double-face corrugated board. It delivers Large Format litho-labels (81" wide x 66" thru) with NO SKIP FEED operation required. A single-source drive controller simplifies the electrical system design and operating programs. A display panel provides the operator with easy-to-use menus and screens for fingertip control of the laminating process. The Model 8166 has stationary machine components with tilt-down transfer units to allow easy access for machine setup, equipment additions, cleanup and routine maintenance.

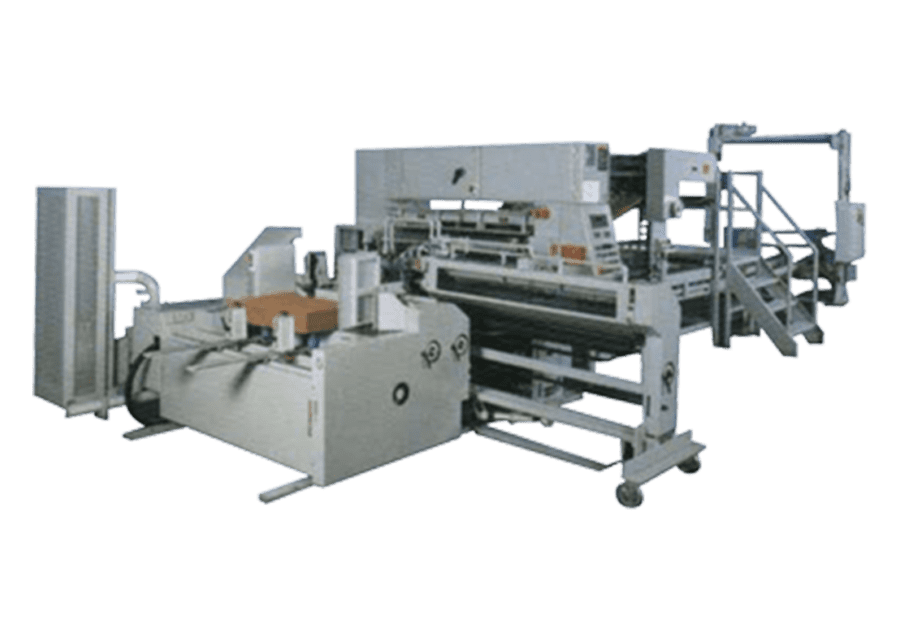

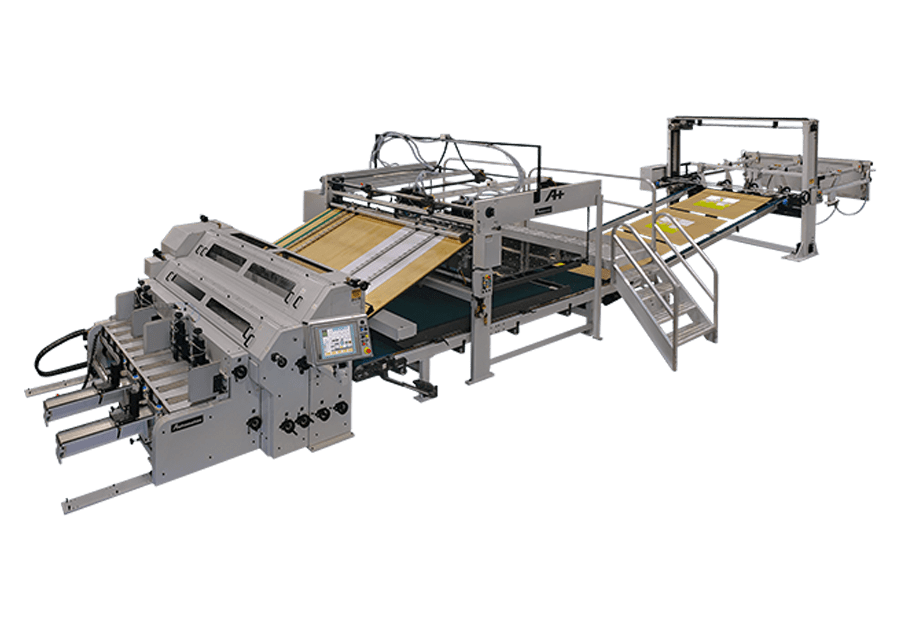

Model A+ Litho-Label Laminator

The Model A+ Lith0-Label Laminator is the newest member of the labeler family. The A+ offers the record-breaking ability to adhere an 81" (2055 mm) litho-label at speeds up to 6,000 sheets per hour utilizing its patented electrostatic application method. The A+ is versatile and dependable with single-face module, 6,000 sheets per hour, 81" x 65" litho label format, dual label/dual board, dynamic board registration, and standard water cleanup.

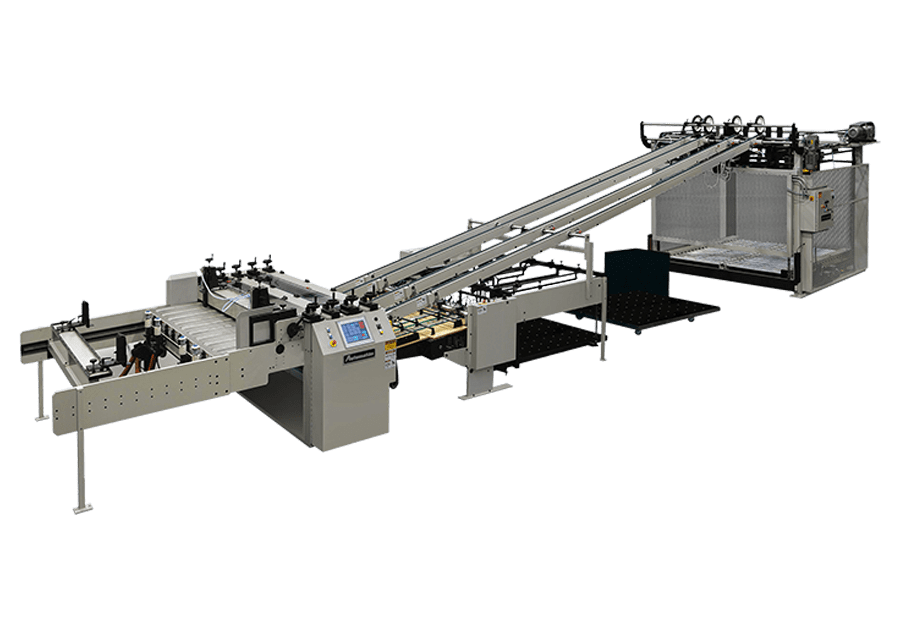

Model EM Litho-Label Laminator

The Automatan Model EM Litho-label Laminator applies Electrostatic Method technology in its adhesive application process. An economical labeler, the Model EM’s design offers the opportunity to employ the electrostatic method for fast, easy setups in labeling over a wide range of board and label sizes. The Automatan Model EM Litho-Label Laminator has been designed and configured as a versatile machine to be used in a variety of applications.

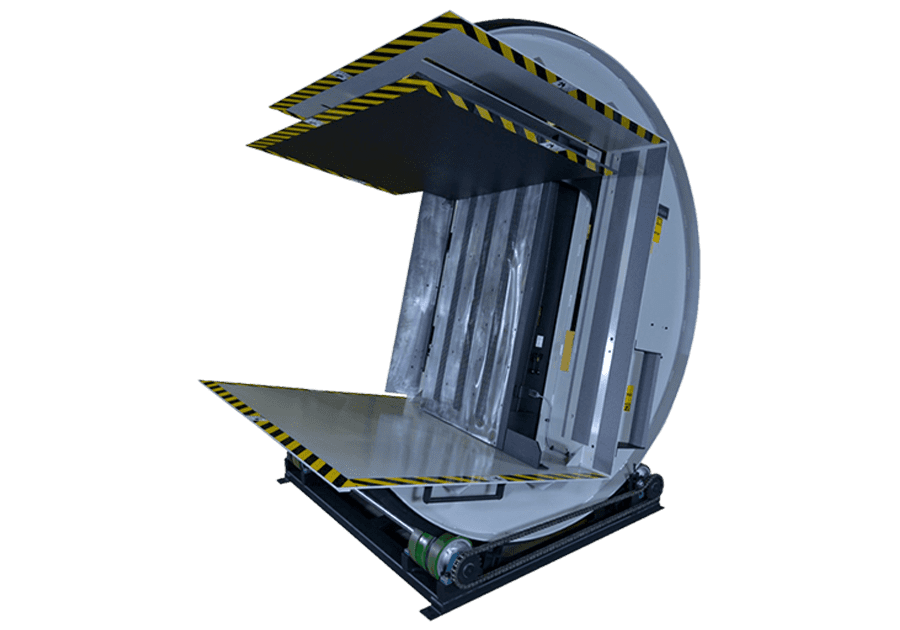

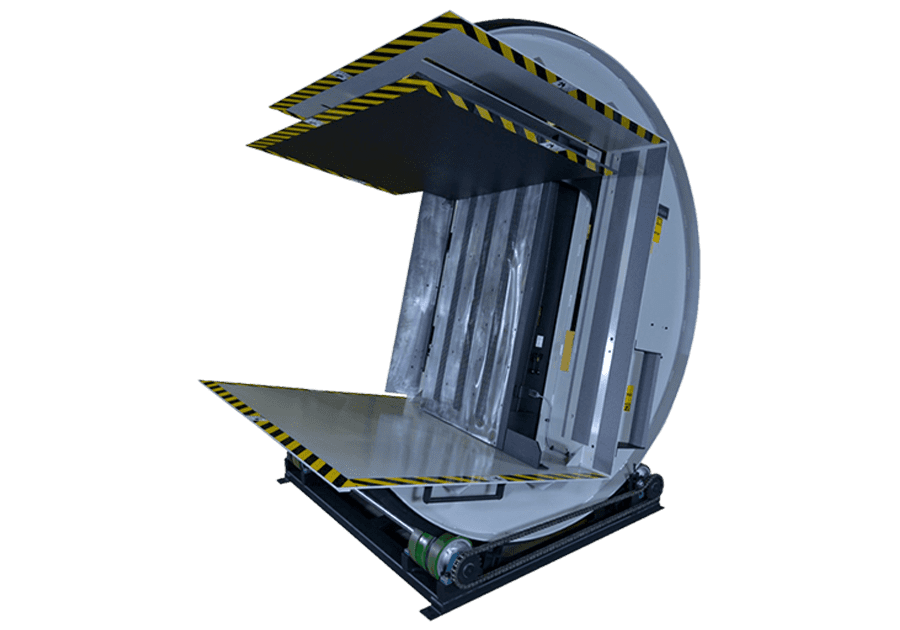

Load Turners

Jogger-Aerators

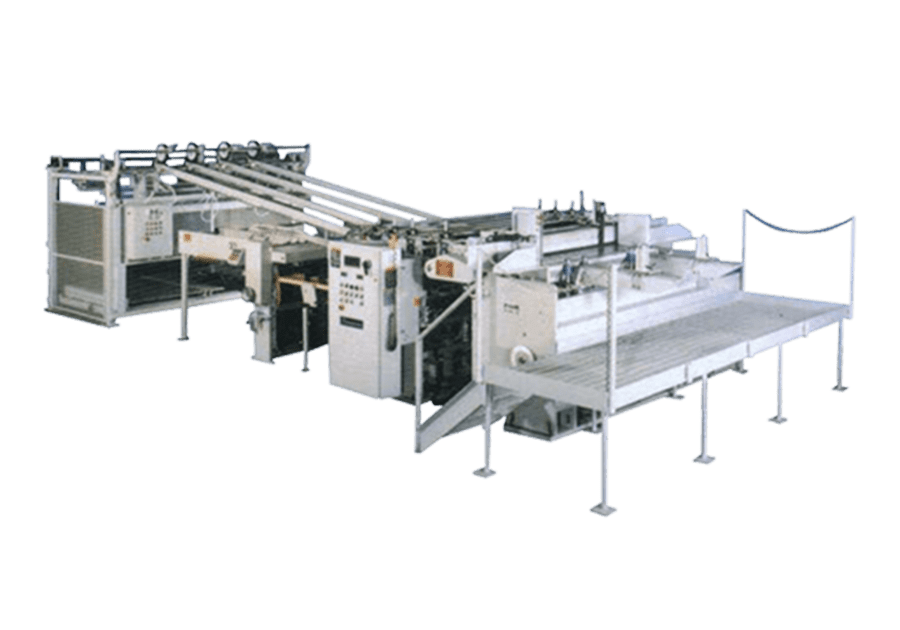

Whether turning, jogging, or aerating large sheets in a printing operation, or changing pallets for shipping, manual handling of large loads can be time-consuming and expensive. The Automatan Jogger/Aerator reduces these tasks to a simple one-person operation that produces an evenly stacked pile of sheets in a fraction of the time required for manual aerating and stacking. Designed specifically to turn, jog, square, aerate, and clean loads of paper, board, and plastics, the Automatan Jogger/Aerator product line is built to be placed anywhere in the plant. Automatan has several J/A models to provide flexibility in load size and load orientation, ensuring that one of our various models will meet your application needs.

Jogger/Aerator

Load Handlers

Whether turning, jogging, or aerating large sheets in a printing operation, or changing pallets for shipping, manual handling of large loads can be time consuming and expensive. The Automatan Load Handler reduces these tasks to a simple one-person operation that produces an evenly stacked pile of sheets in a fraction of the time required for manual aerating and stacking. Designed specifically to turn, and square loads of paper, board, and plastics, this Automatan Load Handler models are built to be placed directly on the floor anywhere in the plant. Automatan LHE provide flexibility in load size and load orientation, insuring that one of our various models will meet your application needs.

Model 7300

Whether turning, jogging, or aerating large sheets in a printing operation, or changing pallets for shipping, manual handling of large loads can be time-consuming and expensive. The Automatan Jogger/Aerator reduces these tasks to a simple one-person operation that produces an evenly stacked pile of sheets in a fraction of the time required for manual aerating and stacking. Designed specifically to turn, jog, square, aerate, and clean loads of paper, board, and plastics, this Automatan Jogger/Aerator Load Turner model is built to be placed directly on the floor anywhere in the plant. Automatan J/A models provide flexibility in load size and load orientation, ensuring that one of our various models will meet your application needs.

Model 8300

Whether turning, jogging, or aerating large sheets in a printing operation, or changing pallets for shipping, maual handling of large loads can be time consuming and expensive. The Automatan Jogger/Aerator reduces these tasks to a simple one-person operation that produces an evenly stacked pile of sheets in a fraction of the time required for manual aerating and stacking. Designed specifically to turn, jog, square, aerate, and clean loads of paper, board, and plastics, this Automatan Jogger/Aerator Load Turner model is built to be placed directly on the floor anywhere in the plant. Automatan J/A models provide flexibility in load size and load orientation, insuring that one of our various models will meet your application needs.

Model 6500GL

Whether turning, jogging, or aerating large sheets in a printing operation, or changing pallets for shipping, manual handling of large loads can be time-consuming and expensive. The Automatan 6500 GL Jogger/Aerator reduces these tasks to a simple one-person operation that produces an evenly stacked pile of sheets in a fraction of the time required for manual aerating and stacking. Designed specifically to turn, jog, square, aerate, and clean loads of paper, this Automatan Jogger/Aerator is built to be placed directly on the floor anywhere in the plant without the need for a pit. As with other Automatan J/A models, the 6500GL provides flexibility in load size and load orientation, ensuring that one of our various models will meet your application needs.

Support Services

Technical Support Services

Find the latest upgrades and improvements available for your Inspire Automation equipment.

- Remote Technical Support: M-Guard and AutoView Remote Monitoring Systems

- Inspire Advantage Program: Long-Term (Annual) Service/PM Program

- Service Audit Programs

- After-Hours Service Support

- Remote Service Technology

Product Support Services

Get support relating to the specific products currently being used in your operation.

- Spare Parts Packages

- Dedicated Spare Parts Fulfillment Center

- Support for Other OEM Products

Product Features and Benefits

Our product features enable you to maximize the operation and efficiency of your equipment.

- Fewer Direct Connect drives

- ASI Framework—Less Wiring

- Less Hardware with Welded Frames

- Fewer Bearings, Sprockets, and Chains

- Fixed, Laser-cut, Pressure Racks with No-Stop Bolts

- Maintenance-free Gear Motors

- Lifetime Lubricated Bearings

Technical Support Services

Product Support Services

Product Features and Benefits

Get in touch

Interested in Our Labeler & Load Turner Solutions?

Whether you’re looking for service, ordering replacement parts, need a quote on a product, or simply have a question, we’ll be happy to assist you.

Send Request