Why Automated Solutions Are Crucial for Manufacturers

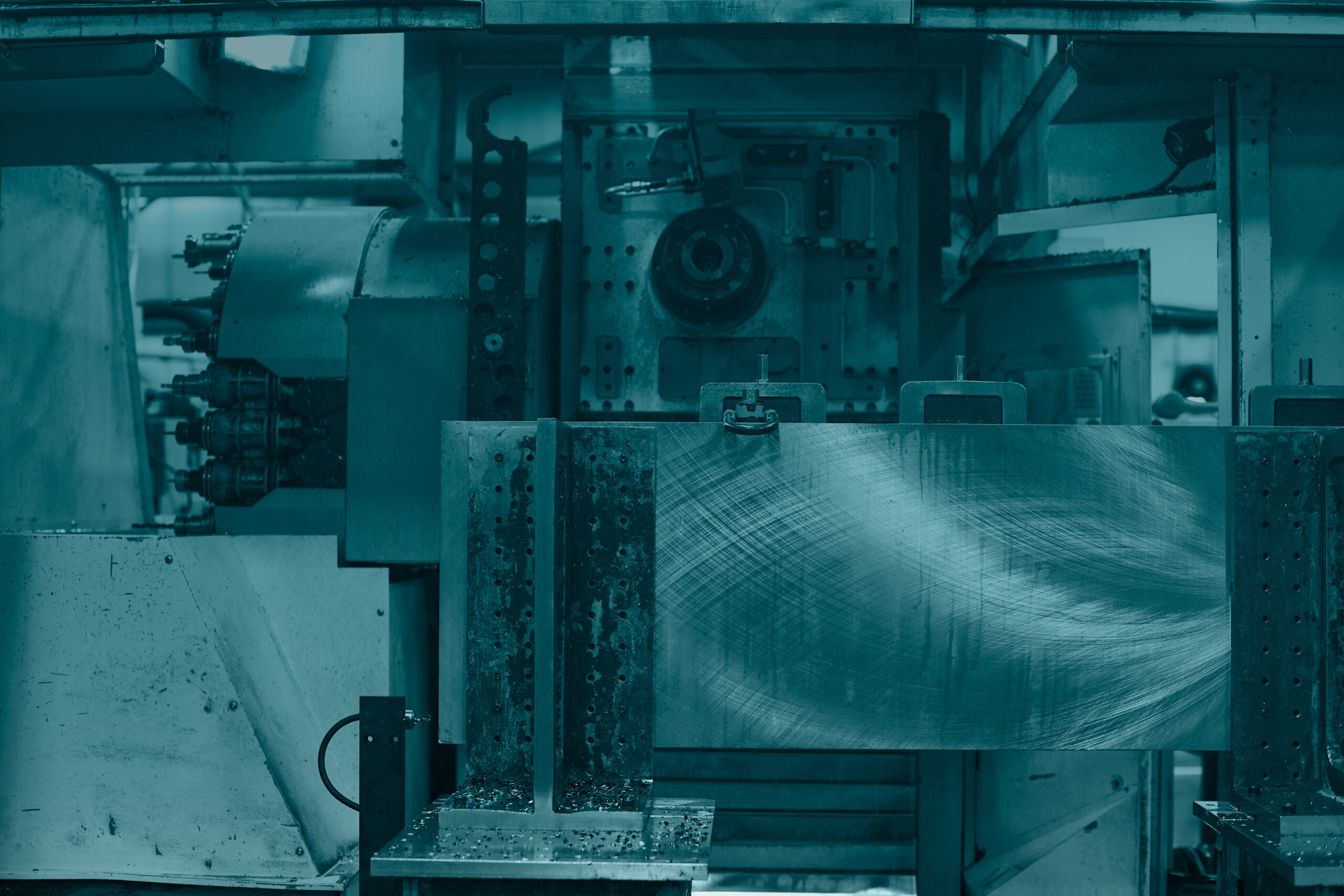

In the field of manufacturing, technology is vital for long-term success.

This is a sector where operations are handled under very demanding conditions. To balance high levels of demand in terms of production volume, product quality, and process safety, it’s very helpful to embrace new technologies.

Automation has been a part of the field for over a decade. However, today’s facilities are embracing it in more applications than ever before.

In manufacturing facilities of all sizes and specializations, automation is becoming a must-have tool. Today we’ll discuss why every facility manager in this field should embrace this technology and how we here at Inspire Automation can provide the right options for your needs.

A Brief History of Automation in the Manufacturing Industry

Automation in manufacturing has a rich history that spans centuries, evolving from simple mechanical systems to sophisticated robotics and artificial intelligence. The journey began with the Industrial Revolution in the late 18th century, where water and steam power were harnessed to mechanize tasks like weaving and spinning, revolutionizing textile production.

The early 20th century witnessed the advent of assembly lines, pioneered by Henry Ford in automobile manufacturing. This breakthrough streamlined production and reduced costs, making mass production more accessible.

The mid-20th century marked the rise of computer numerical control (CNC) machines, which could execute precise, repetitive tasks with greater efficiency and accuracy. Robotics became a key player in manufacturing during the latter half of the century, automating tasks across various industries.

In recent decades, the integration of sensors, data analytics, and artificial intelligence has further transformed manufacturing. Smart factories, known as Industry 4.0, leverage automation, the Internet of Things (IoT), and real-time data to optimize production, reduce errors, and enhance customization.

Today, automation is not only about mass production but also about flexibility, customization, and sustainability. As technology continues to advance, manufacturing automation continues to evolve, reshaping industries and paving the way for a future where humans and machines collaborate to drive innovation and efficiency.

What Are Some of the Most Popular Automation Solutions?

Given that automation has been evolving steadily over the past years and decades, it stands to reason that there is a wide array of solutions to choose from for your facility.

We provide a number of high-quality automation options, each optimized to deliver the value, reliability, and safe performance you seek in any type of equipment. If you’re looking to implement automation technology into your operation, consider solutions like:

- Material Handling Automation: Our corrugators, conveyors, belt transfer devices, rollers, and other transfer-based hardware can help you easily move everything from materials for in-progress projects to finished products ready for shipping.

- Robotic Automation: With our robotic automation options, you can streamline load forming processes and enjoy efficient feeding solutions, effectively speeding up your workflows for a more productive operation.

- Labelers and Load Turners: Our labelers and load turners provide critical functions in your workflows, allowing you to speed up your operations while also ensuring peak efficiency from beginning to end.

With these options in your facility, you’ll enjoy smoother and more seamless processes. Automation solutions are proven to provide the functionality that manufacturing operations need, while maintaining high levels of quality and consistency.

For some manufacturing managers, their one objection to implementing these solutions lies in the fear of technical problems. When you work with Inspire Automation, we’ve got you covered and we’re here to support you completely.

We Offer Top-Quality Technical Support Services

When you get any manufacturing automation solutions from us, you can also count on us for the technical support and product support services you need.

We’ll help you understand all the product features and benefits available to you. We’ll also help you handle any problems that arise. We offer remote monitoring, long-term service plans and audit plans, and even after-hours support so you’re always covered.

We’re not just an automation provider—we’re a proven partner who supports manufacturing operations to the fullest.

Top Benefits of Using Manufacturing Automation Solutions

Manufacturing automation solutions offer a multitude of benefits that contribute to the success and competitiveness of industries.

Automation can significantly reduce labor costs over time. The long-term savings from increased productivity and reduced errors are substantial.

Automation doesn’t necessarily replace human workers but often enhances their roles. It allows employees to focus on more creative and strategic tasks, improving job satisfaction and reducing repetitive, mundane work.

These systems can operate 24/7 without fatigue, leading to faster and more consistent production. This, in turn, enables businesses to meet customer demands promptly. They also minimize the risk of human error, leading to improved product quality and consistency. This results in fewer defects and better customer satisfaction.

Additional benefits include:

- Easier compliance with industry regulations and standards

- Higher levels of safety by tasking robots with dangerous tasks

- Convenient access to data and analytics from automated systems

- Easier path to making customized or complex products

- Support for scaling up while keeping costs under control

- Reduced energy usage to support sustainability initiatives

- Competitive advantage over other facilities in your sector

In conclusion, manufacturing automation solutions offer a comprehensive range of benefits, from cost savings and improved quality to enhanced safety and environmental sustainability. Embracing automation can empower businesses to thrive in a rapidly evolving and highly competitive global marketplace.

If you’re ready to implement high-quality automation solutions at your facility, we here at Inspire Automation are excited to work with you. Reach out today to learn about our high-quality hardware and support solutions. The world of manufacturing is changing, so let us be your partner for this exciting journey.

More from the Blog

Importance of Having Robust Software in the Automation Industry

Discover how robust software solutions like PLCs, HMI, DCS, and SCADA can enhance efficiency and productivity in industrial automation.

Read Full Article

Streamlining Material Handling in Non-Corrugated Facilities: Inspire Automation’s Tailored Solutions

Discover Inspire Automation's customized material handling solutions for non-corrugated industries. Improve efficiency and save costs with robotic and automation technologies.

Read Full Article